Hydropower project

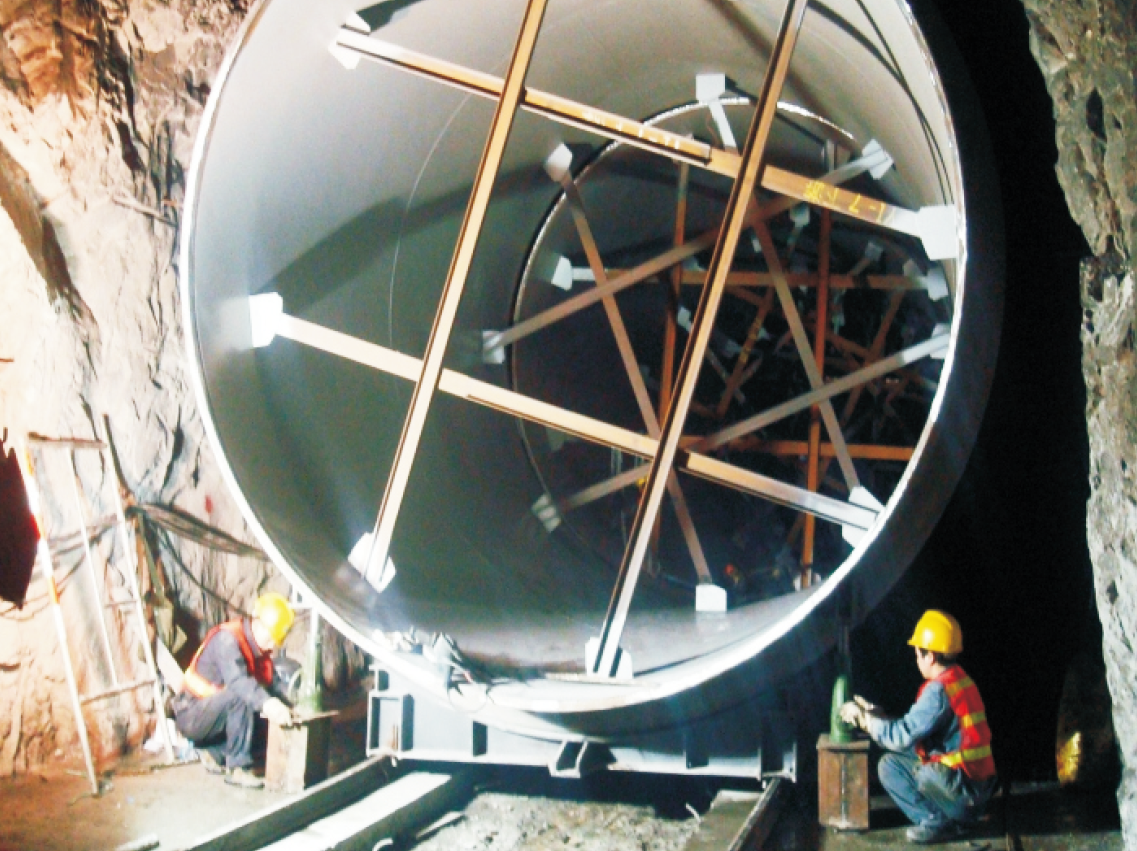

Yunnan Gongguoqiao Power Station Pressure Steel Pipe Fabrication and Installation Project

Gongguoqiao Hydropower Station is located in the middle reaches of the Lancang River. Our company is responsible for the fabrication, transportation, and installation of the penstocks, with a total volume of 2200 tons. The inner diameter of the penstocks ranges from 7.73 to 11 meters. The penstocks are buried underground, made of 16MnR steel plates with a thickness of 32 mm. They are variable diameter pipes with a large diameter and thick plates, making on-site lifting, transportation, and welding challenging aspects of the project.

The Mengkai River-Reservoir Connectivity Project is a near-term project of the Dianzhong Water Diversion Project. The total length of the water diversion route is 51.913km (including the spillway). The design water diversion flow rate is cubic meters/second. The project includes the Nandong cascade pumping station and the Changqiaohai pumping station, with pipe diameters of 1.4M and 2M. It also includes 11 branch pipes, cross-river arch pipes, expansion joints, and pressure pipes with diameters of 0.7-2m, as well as gates, trash racks, and sluice gates.

Installation project of pressure steel pipes for Shenzhen pumped storage power station

The Shenzhen pumped storage power station has an installed capacity of 1200 MW. The powerhouse waterway system adopts a 1-pipe, 4-machine water supply method, with the water intake branch pipe being a buried pressure steel pipe. The inner diameter of the steel pipe is φ4 meters, the steel pipe material is 600 MPa high-strength steel, the plate thickness is 50 mm, and the total weight is 2700 tons. The welding process has high requirements for welding temperature and requires complex processes such as preheating before welding, post-weld heat preservation, and interlayer temperature control.

The Niulan River-Dianchi Lake Water Supplement Project

This project involves the construction of a water conveyance pipeline from Deze Reservoir using a pumping station. Our company is responsible for the fabrication and installation of 2000 tons of pressure steel pipes at the dam, as well as the installation of gates, trash racks, hydraulic trash cleaning machines, intake well sluice gates, a 70-ton, 2.8-meter diameter conical valve, and mobile hoists. The pressure pipeline is mainly located in the lower section of the generator tunnel. The main steel pipe has a diameter of D=4 meters. The irregular and narrow excavation inside the tunnel makes construction very difficult, so a track flatcar lifting installation method was adopted. The sluice gate is large, weighing 75 tons, and is located 120 meters above ground level. The hoisting location is narrow, making hoisting difficult.